SPECIFICATIONS

Advantages: Light Weight, fire proof

After-sales Service Provided: Engineers available to service machinery overseas

Application: Building Materials Machinery, shopping center

Automatic Grade: Automatic

Brand Name: Hongfa

Color: Customized

Core Components: PLC,Motor

Dimension(L*W*H): 3380*3200*2680mm

Features: easy to maitain

High capacity: 50,000m2 to 500,000m2/year

Key Selling Points: Hot Product 2023,Long Service Life

Machinery Test Report: Provided

Main materials of Wall slab: Cement/fly ash,sand,foam polystyene particles

Place of Origin: Guangxi, China

Power(W): 4kw

Product name: lightweight concrete wall panel forming machine

Production Capacity: 680-800kg/ m³

Production data: Can be recorded by computer

Raw material: Fiber cement board, EPS, Cement, Sand, Foam agent

Video outgoing-inspection: Provided

Voltage: 220v--380v

Warranty: 1 Year

Weight: 8600 kg

installation: Guided by us

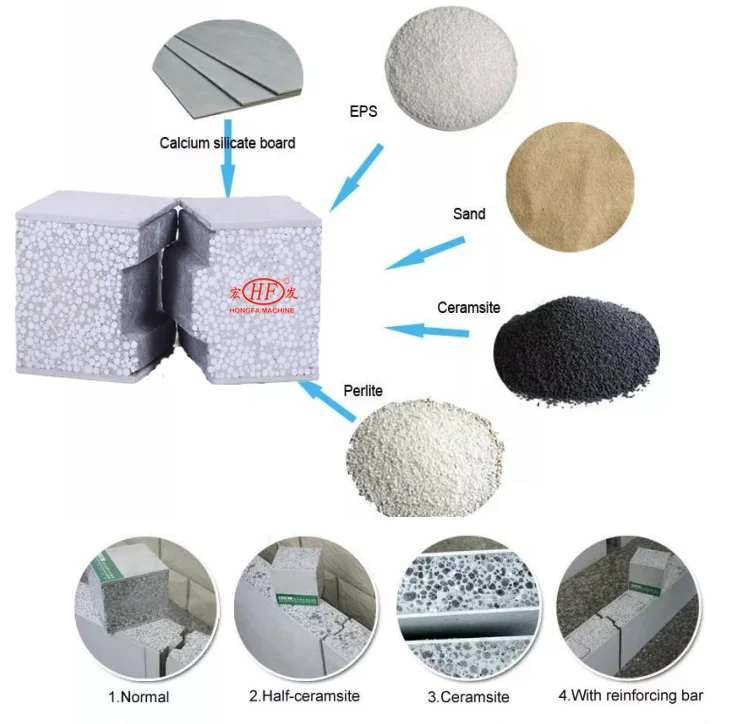

Raw Materials

1. Good thermal isolation EPS bonding mortar as core material.

2. Calcium silicate board / Fiber cement board as the surface material.

3. Properly mixed with fly ash, slag and additives.

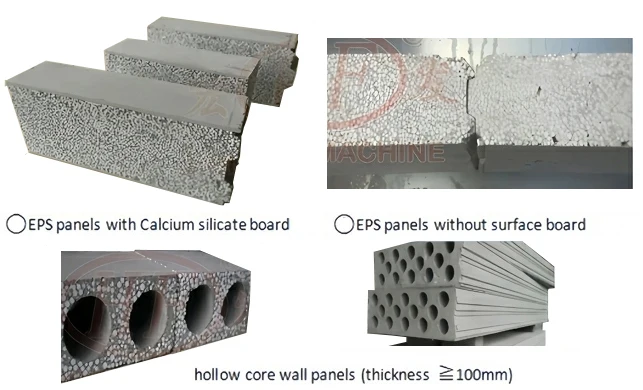

Our machine support making different Kinds of wall panels, like solid panel,hollow panel,By changing the mold, panels of different thicknesses and lengths can be produced.

For more needs, please feel free to contact Ms. Tina:+8618275773233

Main Parts of Production Line

Layout of EPS Lightweight Panel Production Line

1,Silo:storage cement/fly ash

2,Boiler: generates steam for the EPS expander

3,EPS Expander:Produce the foam EPS beads

4,Mixer:mix the raw materials into fine slurry

5,Filling Platform:fill the slurry into the mold car

6,Ferry Car: transport the mold car to the curing rails

7,Mold Car: form the EPS wall panel and curing

8,Winch Machine: move the mold car on the rails

9,Demolding and Stacking Machine: pull out the finished wall panel from the mold car and stack the panels for the forklift to transport to storage area.

1. Mixing plant

HONGFA mixing plant consists of mixer, movable infusion unit and aggregating system. It can mix all raw material automatically and record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a

panel with size 2440*610*100mm.

2. Boiler & EPS Expander

Boiler and EPS expander is used for expanding raw polysterene, one-time expander can make EPS around 7-18kg/CBM, interval expander

can get proportion on 3.5-6kg/CBM.

3. Molding machine

a. Has 4 cylinders at both sides for turning. The machine can turn down at both size with any angle. For easy to the workers. As after turn down, it is only about 1.3M high, that is the optimal high for human force. So you can work faster and not tire.

b. It is automatic opening and closing, no manual screw cap fixing screw is required ( for the fake automatic machine, even it has the system to open and close, but still need manual to fix pressure bar .

c. Every machine has its own hydraulic system and control box.

d. It can turn itself, no need other machines to

assist. Can operate multiple machines at the

same time, high efficiency: save time, save labor e. Bottom with square steel 200* 100* 10mm, the machine weight is up to 5800kg ( for 2440 length panel type)

4. Demoulding system

a. The demoud l machine can moving, push out the panels and stacking up the panels for transport by forklift. b. It can move and demoudling anythere, more flexible

c. It can assisit to transport aluminium moulds

d. It also can assisit to set up the aluminium moulds into the machine, for faster precessing when the demould machine free.

5. Waste recycle system

To fully use the waste water and waste

slurry, to avoid pollution of the environment, here is the recycle system:

a. Waste tank

b. mixer

c.slurry pump. This pump has the lifting

function. When do not pump, it can be lifted up, to avoid mortar blockage

6. Moving system

a. Ferry to transport the mould cars to curing area and demoulding area.

b. Using 18# rail for the mould cars moving

c. Spead slip line for offering cable to mould cars, ferry and demoulding

machines.

7. Control system

a. PLC control system (the system has fully automatic and manualy two options during production) automatic. With Simens system and ABB control key.

b. All raw materails like water, cement, sand, additive, EPS, can be autoamtic batching,

weighing, delivery, input, mixing, discharge

according tot he setted formula. And also can record and print daily production data. One key control all.

c. By technology updated and full automatic PLC control system applied, the mixing time is only 7 minutes per cycle.

For more information on the lightweight panel production line, please feel free to contact Ms. Tina:+8618275773233

Free Inquiry and Consultation

- Free inquiry and consulting support on analyzing customers' needs and market prospect.

Free Solution to Set up a Factory

- Provide perfect solution to set up a factory to perform EPS sandwich cement wall panel machine operation.

From the day our products sold, we will promise to do as follows:

(1) Provide corresponding technical solutions and site layout;

(2) Provide guidance equipment installation and operation for users.

(3) For each equipment ,we will train mainly operating personnel 5-10.

(4) 12 months guarantee, and provide lifelong technical support.

(5) Feedback within 24 hours after consulting.

(6) Build customers using and maintaining files as soon as dispatch machines;

(7) After finish debugging of equipment, users inspect and sign the acceptance certificate according to the situation of site service.

MS.Tina

whatsapp:+86 18275773233